Cut ties with pre-wetted plastic surface disinfection wipes

Are you looking to reduce single-use plastics in your surface disinfection protocol? Start by taking out pre-wetted plastic wipes.

Right now, in hospitals around the world, staff are wiping down surfaces with detergents and disinfectants. This job never ends, and for good reason. Daily infection control measures like surface wiping are essential to maintain a safe environment for patients and staff.

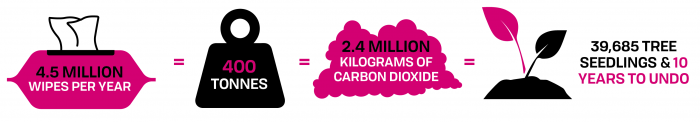

Procurement figures show the National Health Service (NHS) in the UK bought over 4 ½ million surface wipes in one year, pre-pandemic. To put that figure into perspective, it equals 400 tonnes of wipes.

Fast forward to March 2020, and every detergent and disinfectant pre-wetted wipe product sold by the NHS Supply Chain hub went out of stock.

Why are so many pre-wetted wipes used in the NHS?

Pre-wetted wipes are the most commonly used product for the NHS’s disinfection requirements, and are typically made of and packaged in single-use plastic. The design ensures detergent or disinfectant solution is effectively carried from point of manufacture to point of use without any degradation of the wipe, the chemical, or their combined ability to kill microorganisms.

The big problem is that when you use a pack or tub of pre-wetted plastic wipes for disinfecting surfaces, your impact on the environment is decided for you. After each single use, you throw the plastic wipe away.

What can be done to remove single-use pre-wetted plastic wipes?

Single-use pre-wetted plastic wipes are vital for many medical areas and devices to ensure effective decontamination and avoid outbreaks. However, they can and should be eliminated for surface disinfection, without impacting the efficacy of your hospital’s disinfection protocol.

Tristel achieves this by separating powerful chlorine dioxide (ClO₂) chemistry from the wipe until point of use. Thanks to EN 16615 compliance, hospitals can use their choice of wipe, enabling them to create the most cost-effective and eco-friendly sporicidal wipes on the go.

Have you met JET PRO?

JET PRO is a sporicidal foam, proven effective in just one minute and is available now.

Each bottle of JET PRO delivers 570 doses of ClO₂ foam. Reducing disinfectant waste, surfaces are targeted with a freshly delivered chemistry stream, rather than offloading aerosols that circulate in the air and around patients.

Use any eco-friendly wipe for sporicidal efficacy, with EN 16615 and EN 17126 compliance.

Thanks to EN 16615 standard wipe compliance, you can pair JET PRO with any spreader. Choose any microfibre cloth or more environmentally friendly dry wipe, without sacrificing EN 17126-compliant sporicidal efficacy.

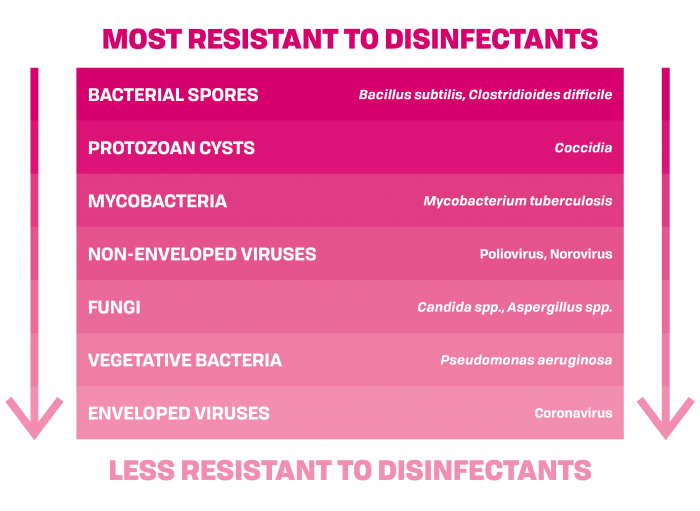

Sporicidal efficacy is the highest level of disinfection for surfaces and can only be claimed by showing EN 17126 compliance. When chemistry has proven sporicidal efficacy, it provides the highest level of protection. Sporicidal chemistry not only helps to guard against existing pathogens but can shield against new, emerging pathogens too.

A sporicidal disinfectant like JET PRO is also mycobactericidal, virucidal, yeasticidal and fungicidal. JET PRO protects your patients against SARS-CoV-2 and a multitude of other infection risks.

Cut ties to pre-wetted plastic wipes with Cache

JET PRO is part of Cache, an eco-conscious collection of surface disinfection products that ensures you can curb the disposal of single-use throw-away plastic wipes.

The Cache Collection is designed with sustainability woven throughout the product range, from reusable trigger heads that are built to last right through to recyclable bottles and capsules. You can create a complete and sustainable cleaning and disinfection protocol for your hospital.