Prolonged protection explained with JET PRO

Surface disinfectants cannot be used every minute of every day. Here is why the NHS needs infection prevention solutions that last longer in between cleans:

The past few years have seen a surge in the importance placed on good general hygiene, both within hospital walls and beyond. A major source of cross-contamination and infection are frequently touched surfaces. Not only SARS-CoV-2, but many other infection risks such as Clostridioides difficile and Bacillus subtilis pose a challenge. To help combat these risky pathogens, NHS staff follow their standard operating procedures (SOPs) to disinfect areas and surfaces to control the build-up of microbes of concern. But, once disinfection of these areas and surfaces is complete, it can frustratingly be just moments after that frequently touched surfaces are re-contaminated.

Keeping frequently touched surfaces microbe-free for longer

As hospitals have been pushed to step up infection control measures as a result of the COVID-19 pandemic, maintaining effective surface disinfection procedures have come under increasing scrutiny. For frequently touched surfaces in particular, there is no lasting protection for staff and patients as these surfaces are touched more regularly.

Knowing this, hospitals continue to enact extra infection control measures. Across every treatment room and patient waiting area, disinfection products now take pride of place for quick accessibility.

The problem is that everyday disinfectants cannot guarantee frequently touched surfaces will remain disinfected and uncontaminated moments after an NHS staff member has completed their disinfection procedure. Whether considering valuable NHS staff’s time or growing sustainability concerns, the best solution for surface disinfection routines is not to increase orders of pre-wetted plastic wipes and use more to cater for frequently touched surfaces. Instead of adding additional plastic wipes to trolleys, treatment rooms, and waiting areas, a solution should be used that is as effective as it is eco-conscious. After all, we cannot use surface disinfectants every minute of every day.

To tackle the infection risks associated with frequently touched surfaces, a disinfection solution that provides longer-lasting protection has now been developed. So, you can disinfect effectively and provide lasting assurance to patients, staff and visitors, before moving on to your next task.

Lasting protection, less waste – JET PRO is the answer

To support the NHS in their post-pandemic infection control efforts, Tristel developed JET PRO to provide prolonged protection against harmful microbes for frequently touched surfaces.

With JET PRO, staff can deliver a sporicidal foam to surfaces that continues to kill bacteria and enveloped viruses for up to eight hours, after just one application with your chosen wipe.

How JET PRO prolonged protection works

With JET PRO, Tristel is the only company to succeed in combining sporicidal efficacy with residual efficacy.

Using powerful proprietary chlorine dioxide (ClO₂) chemistry, JET PRO delivers a stream of sporicidal foam – killing microorganisms in a rapid one-minute contact time.

Simultaneously a protective shield is placed between the patient and potentially harmful bacteria and enveloped viruses for up to eight hours. The long-lasting protection technology, made of a proprietary polymer, has active components to absorb and attach JET PRO disinfectant to surfaces for prolonged disinfection.

As JET PRO dries, the unique structure of its prolonged protection technology leaves an invisible shield that anchors disinfectant to surfaces. The technology then enables ongoing disinfectant efficacy that is deadly to bacteria and enveloped viruses of concern. As surfaces such as doorknobs, bed rails, elevator buttons and light switches are touched repeatedly, the JET PRO protective shield eventually wears away. To refresh its sporicidal action and long lasting protection, JET PRO can then be reapplied.

Proven long-lasting efficacy with PAS2424 testing

JET PRO is proven effective according to PAS2424, a test method to evaluate a disinfectant’s long-lasting antimicrobial activity. Ensuring that JET PRO provides prolonged protection for NHS front-line requirements, this test takes into account that a surface will be frequently touched between disinfectant applications.

After drying microorganisms and an interfering substance onto a defined surface, JET PRO is then applied. Over 24 hours, three abrasion and re-contamination cycles are performed, simulating the high-touch exposure of the surface in-between disinfectant treatments. The level of any surviving microbes is measured to test the long-lasting efficacy of the disinfectant.

Test data proves that JET PRO provides residual antimicrobial activity for up to eight hours. So, you can ensure disinfection practices deliver maximum results around the shift patterns of NHS staff.

Reducing plastic wipe waste for surface disinfection

The most commonly used product for surface disinfection in the NHS is single-use pre-wetted plastic wipes.

After each surface disinfection procedure with a pre-wetted plastic wipe, the single-use wipe is thrown away. Currently, many disinfection procedures for frequently touched surfaces must take place on repeat to ensure effective infection control.

However, in a world with growing environmental concerns, the rush to increasingly disinfect surfaces has also caused a large increase in the quantities of waste caused by single-use plastic pre-wetted wipes for surface disinfection.

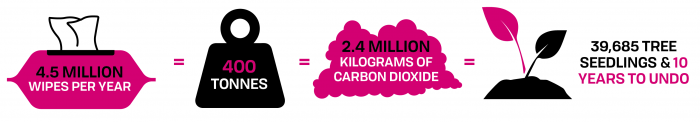

Procurement figures show the National Health Service (NHS) bought over 4 ½ million surface wipes in one year, pre-pandemic. In real terms, that equates to 400 tonnes of surface wipes, which is approximately as heavy as four Blue Whales.

Fast forward to March 2020, and every detergent and disinfectant pre-wetted wipe product sold by the NHS Supply Chain hub went out of stock.

Plastic is often a vital material for medical uses. The plastic design of pre-wetted wipes and their packaging ensures detergent or disinfectant solution is effectively carried from point of manufacture to point of use without any degradation of the wipe, the chemical, or their combined ability to kill microorganisms. But, there are ways we can make plastic use in the medical arena more sustainable.

JET PRO and the Cache Collection – the sustainable option for surfaces

To cut ties with pre-wetted plastic wipes, JET PRO separates the ClO2 chemistry from the wipe until the point of use. JET PRO users can choose their wipe with sustainability and practicality in mind with EN 16615 compliance and without sacrificing EN 17126-compliant sporicidal efficacy. As a result, hospital procurement teams can dramatically reduce the amount of single-use, pre-wetted plastic wipes on order without impacting disinfection efficacy for front-line users.

Going one step further, JET PRO, as part of Cache – an eco-conscious collection of sporicidal surface disinfection products – is designed with sustainability in mind.

Each box of JET PRO comes with two bottles of chemistry – and both the bottles and the caps are recyclable. Plus, as JET PRO trigger heads are built to last, you can reuse them after finishing your bottle.

The Cache Collection brings sustainability into NHS practices, without impacting the safety and sporicidal efficacy of surface disinfection. Create a complete and sustainable cleaning and disinfection protocol for your hospital with Cache, and find out more here.

Stay in the loop: for the latest product news and breaking science, sign up to our network of 7,000+ medical professionals.